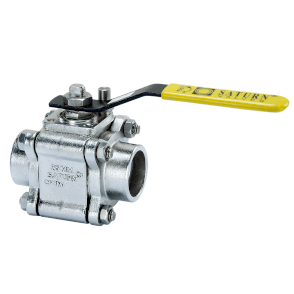

Size |

8-50mm,3/8” – 2” |

Bore |

Full bore |

Ends |

Threaded to BSP-II or NPT

Socket weld to ASN B 16.11 |

Rating |

600 # |

Operation |

Hand lever, Pneumatic/Electrical Actuator |

Material |

Carbon Steel & Stainless Steel |

Seat |

PTFE/RPTFE/TFM1600/NYLON/PEEK |

Design Standard |

ASME B 16.34, BS EN ISO 17292 |

Mounting Pad |

ISO 5211 |

Testing Standard |

API 598 / BS EN ISO 12266-1 |

Face to Face |

Manufacturer's Std. |

Application |

General Process/utilities, In-line maintenance and high pressure lines |

Features |

- Fast & Econimical In-line Maintenance

- Full or Reduce Bore

- Self adjustable gland packing

- Renewable Seat & Seals

- ISO Mounting pad to suit actuator gear box and other hardware mountings

- Maintenance free live loaded double sealing

- High cycle stem packing system provides extra longer service life

- Anti-Static Device

- Blowout proof Stem

- Centering Lugs for easy allignment

- 'O' ring style body seals for better joint sealing & resuable(for Screwed, Socket & buttweld ends)

|

Option |

- Extended 100mm long pre-welded pipes in SW valve to avoid destortion of ball seats

- Extended stem & pad lock capabilities provide maximum safety.

- Vented ball to reduce damage caused by trapped cavity pressure.

- Cavity free seals are available to reduce the possible entrapment of line media fluids between the ball and the shell.

|